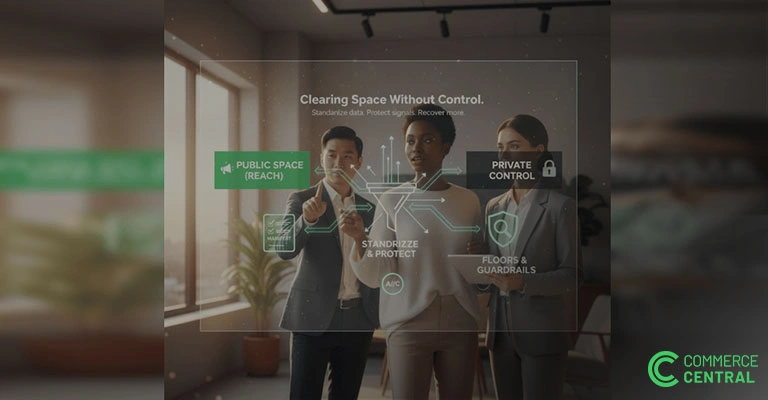

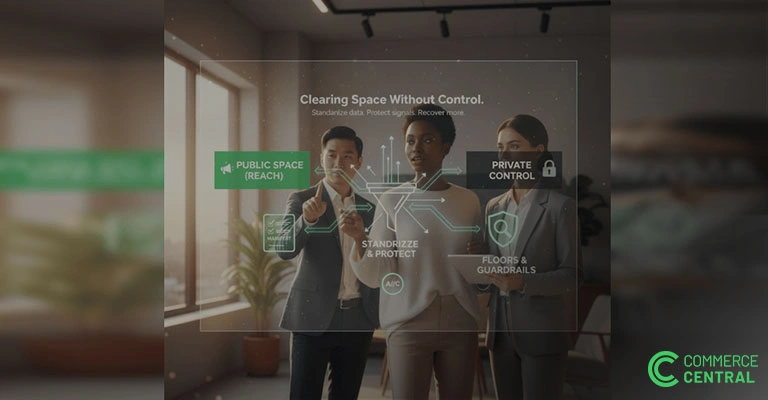

Clearing Space Without Compromise

Improve liquidation predictability with structured data, clear processes, and strong guardrails. Commerce Central delivers faster cycles and higher recovery.

When Tech Doesn’t Turn, Margin Melts and Ops Clog

In electronics, speed is everything. Every product is born with an expiration date. Not because it goes bad, but because it goes obsolete. That’s why aged inventory in this category is uniquely dangerous: it doesn’t just lose value over time, it becomes dead stock.

This article unpacks the real cost of slow inventory offloads in electronics, the operational choke points they create, and a practical framework to assess the damage inside your business.

When electronics don’t move, they don’t just lose value. They jam up space, burn labor hours, delay new launches, and even cause accounting delays due to uncertain valuations. Brands and retailers often underestimate how quickly the damage sets in.

The cost includes:

One CE brand ops director told us: "Our biggest hit wasn’t when we wrote it off—it was when our top retailer refused to take last season’s tablets. We had to reroute 18 pallets to pallet auctions within 72 hours"

Use this 6-point Electronics Offload Cost Calculator to assess the drag within your own system:

Add these up and you’ll see how slow inventory in electronics costs more than just the shelf price, it creates a ripple effect across planning, ops, and profitability.

Slow inventory isn’t just a numbers problem. It’s a morale problem. When operations leaders are forced to spend time triaging stuck SKUs instead of optimizing throughput, the entire organization slows down.

"Every time we delay a new product set to clear out an old one, it kills momentum. It’s a cycle we had to break," said one supply chain VP at a mid-size consumer electronics firm.

Leading electronics brands now treat inventory exits with the same precision they use for launches.

What they’re doing:

Even with great demand planning, some SKUs won’t move. The key isn’t to guess better, it’s to move faster when sales stall.

Commerce Central helps electronics brands route verified surplus to trusted buyers with built-in controls and resale protection. That means faster exits, cleaner manifests, and more control over how your brand is represented downstream.

In a business that moves as fast as the tech it sells, your offload system needs to move just as fast.

Because in electronics, age isn’t just a number. It’s a cost.

Improve liquidation predictability with structured data, clear processes, and strong guardrails. Commerce Central delivers faster cycles and higher recovery.

Avoid audit headaches and compliance risks by properly documenting and tracking inventory offloads, keeping finance and legal teams confident.

Don’t let outdated returns processes slow you down. Discover how reCommerce can digitize the last link of your supply chain and drive efficiency.

Join the only private surplus distribution platform built for trusted Buyers and Sellers.